What Are the Top Industries That Use Overhead Cranes?

Overhead cranes, the titans of material handling, are not merely a feature of the industrial skyline; they are critical drivers of efficiency and productivity in several sectors. Their deployment within various industries and their contributions to enhancing production are manifold, with significant impacts on lead times and capabilities.

Industries with High Utilization of Overhead Cranes

Overhead cranes are integral to the daily operations of many industries. These powerful machines are common sights in environments where large and heavy objects need to be moved reliably and efficiently. Let’s explore the specific sectors that heavily depend on overhead cranes and the unique roles these cranes play in each.

Overhead Cranes and Steel Production

The steel industry presents some of the most challenging environments for material handling equipment. Overhead cranes operating in these conditions showcase their robust design and reliability, managing the entire workflow of steel production from raw material to finished product. In steel foundries, overhead crane systems for steel production facilities are essential for the heavy lifting and precise positioning of molten steel and large casts, playing a vital role in the workflow, from the smelting process to the cooling and finishing stages, significantly enhancing productivity and worker safety.

Custom Overhead Crane Solutions for the Automotive Industry

The automotive industry’s relentless drive for efficiency finds a perfect partner in overhead cranes. These cranes are the workhorses behind the scenes, facilitating the swift and precise assembly of vehicles by handling major components with ease.

Overhead Cranes in Shipping and Logistics

Speed and efficiency in shipping and logistics have a direct impact on global trade. Overhead cranes are the powerhouse tools that keep cargo moving in these critical junctions of the supply chain, helping to maintain the pace of commerce.

Overhead Cranes for Manufacturing

In the manufacturing realm, overhead cranes fulfill crucial roles in the production pipeline, from the initial stages of handling raw materials to the final phases of shipping completed products. Their presence is a testament to the emphasis on efficiency and safety in material handling.

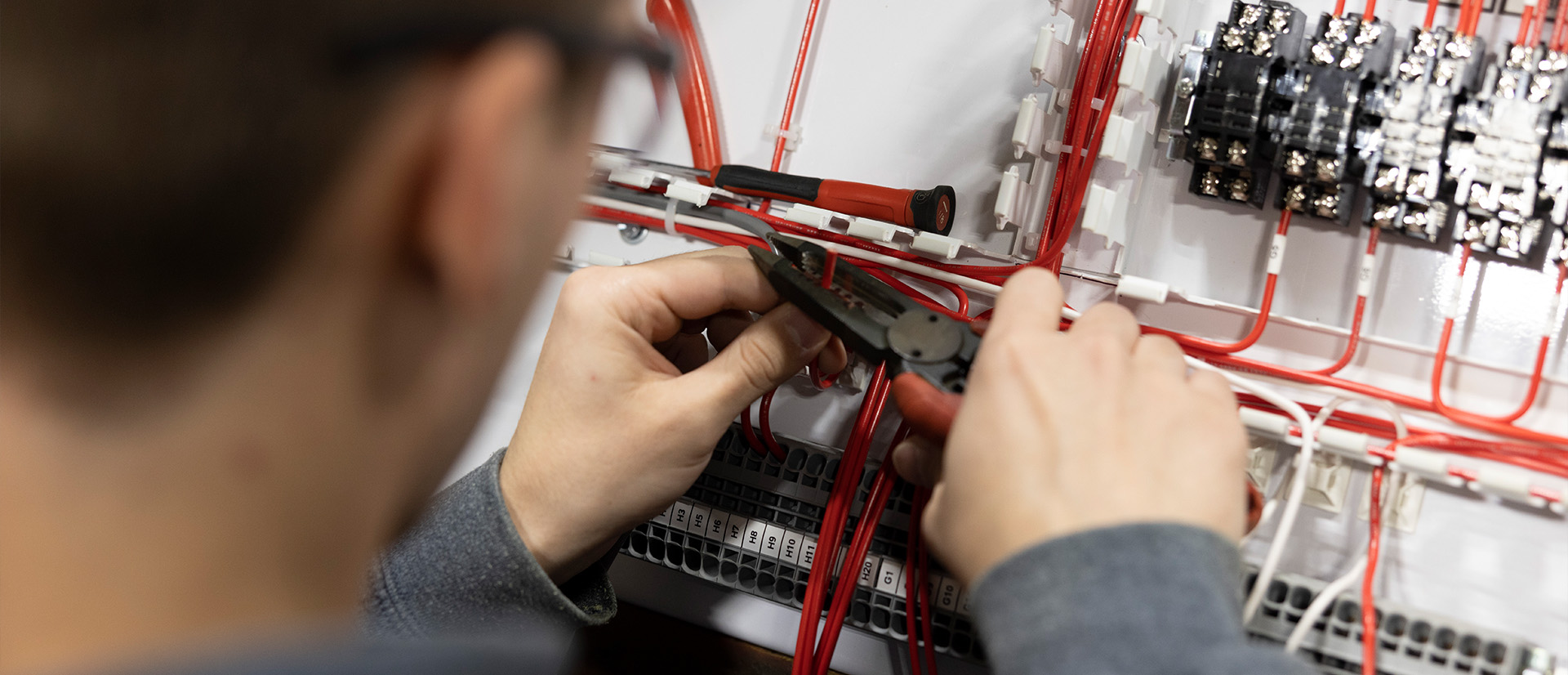

Overhead Cranes for Utility Companies

Utility companies often require the handling of heavy equipment and materials, ranging from transformers to reels of cable and sections of pipe. Overhead cranes play a crucial role in the maintenance and service areas of these companies. They enable the safe and efficient movement of such items, particularly in restricted spaces where precision is paramount. The ability to maneuver delicate equipment into place without damage is vital in the utility sector, where downtime due to equipment failure or damage can have significant consequences for large populations. The use of overhead cranes in these scenarios not only aids in reducing the risk of workplace injuries but also enhances the ability to perform maintenance and installation tasks more efficiently, thereby helping to ensure a continuous supply of essential services like electricity, water, and gas.

Overhead Cranes in the Paper and Pulp Industry

The paper and pulp industry is another sector where overhead cranes are indispensable. In this industry, they are used to handle raw materials such as wood chips and pulp, as well as large rolls of paper and heavy equipment. The cranes are essential for maintaining a smooth and efficient workflow, from the initial stages of production to the final stages of packaging and distribution. With their ability to lift and transport bulky items in a controlled manner, overhead cranes help reduce the risk of damage to the products and increase overall safety for workers.

Functional Enhancements by Overhead Cranes Across Industries

Overhead cranes not only serve their primary purpose of lifting and moving heavy loads, but they also bring about significant improvements in production efficiency and facility capabilities. These enhancements translate into tangible benefits for the industries they serve.

Overhead Cranes Reducing Lead Times

Responding to market demands with speed is critical for any industry. Overhead cranes play a pivotal role in shrinking the timeline from production to delivery, allowing businesses to fulfill orders faster and more reliably.

Capabilities Amplification Through Overhead Cranes

From increasing operational safety to optimizing workspace, overhead cranes offer a multitude of capability enhancements. These improvements are felt across the board, driving industries to new heights of productivity and operational excellence.

Heavy Machinery Lifting Solutions with Overhead Cranes

When it comes to the lifting and transporting of heavy machinery, overhead cranes offer solutions that are not just about brute strength but also incorporate precision and control. Industries that manufacture or utilize large machinery, such as construction equipment, agricultural vehicles, or mining apparatus, depend on robust cranes to handle these substantial assets.

The cranes must be adept at maneuvering complex loads through tight spaces, often in challenging work environments. They often feature advanced technologies such as anti-sway systems and custom lifting attachments to facilitate the safe and efficient handling of machinery. This not only helps to prevent workplace accidents and machinery damage but also significantly improves the workflow, reducing downtime during machine setup, maintenance, and relocation. The strategic use of overhead cranes in these contexts not only bolsters operational efficiency but also plays a critical role in extending the lifespan of the heavy machinery through proper handling.

In summary, overhead cranes are indispensable across various heavy industries, where they serve as the backbone of production and logistics operations. By reducing lead times and expanding capabilities, these cranes not only enhance productivity but also provide a competitive edge to the industries that depend on them.

Elevate Your Operations with Zenar

At Zenar, we understand that every material-handling challenge requires a tailored solution. As a family-owned manufacturer of custom overhead cranes and material-handling applications, we take pride in our American-made heritage and dedication to craftsmanship, right here in Oak Creek, Wisconsin. Under the leadership of our president, John C. Maiwald, we’ve committed ourselves to elevate industries with our world-class manufacturing capabilities. We don’t just build cranes; we forge long-term partnerships, ensuring that each piece of equipment is a testament to reliability and ingenuity. Let us be a part of your success story.

If you’re ready to enhance your operations with a trusted, precision-engineered crane solution, start your project with us today and experience the Zenar difference. Contact us today to fulfill your custom overhead crane needs.

Read

More

Articles

Overhead Crane Electrification: Innovations in Power Supply and Efficiency

Overhead cranes are indispensable in modern industrial operations, tasked with moving and lifting heavy loads with precision. The functionality of these cranes hinges significantly on their electrification systems, which provide the necessary power for operation and ensure smooth, safe performance.

The Essential Components of an Overhead Crane

Overhead cranes are integral to the operations of numerous industries, serving the critical function of lifting and transporting heavy materials with precision and efficiency. Understanding the various components that make up these complex machines is key to appreciating their design, their functionality, and the role they play in enhancing workplace safety and productivity.

Five Signs Your Overhead Crane Needs an Inspection

In the realm of industrial operations, overhead cranes play a pivotal role in maintaining the flow of materials and products. These mechanical giants are the backbone of numerous sectors, including manufacturing, construction, and logistics, where they lift, transport, and position heavy loads with precision.