Understanding Collision Avoidance Systems

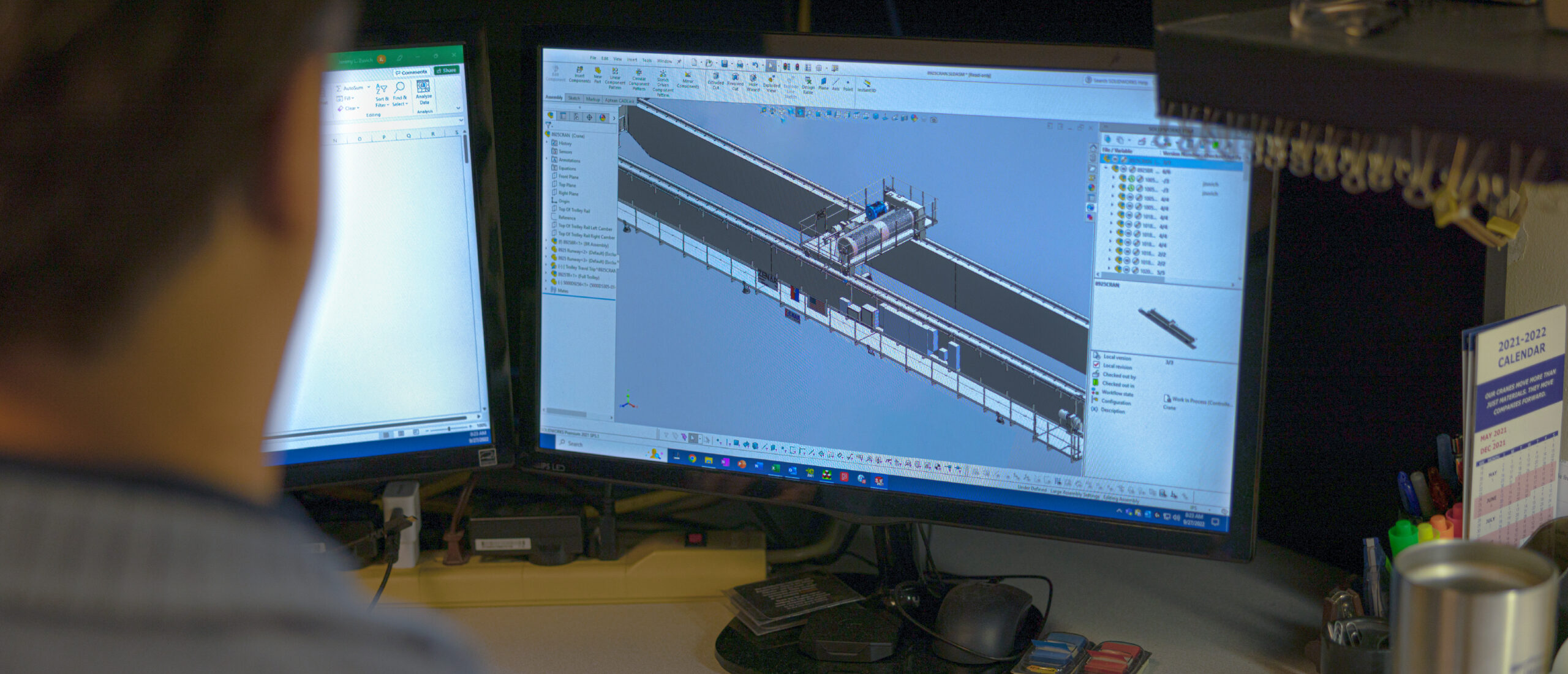

Zenar specializes in providing high-quality overhead crane solutions while prioritizing safety and efficiency in our operations. With a strong reputation in the industry, Zenar has become a trusted partner for businesses looking to optimize our lifting and material handling processes. Our commitment to safety is evident in our innovative approach and advanced technologies tailored specifically for overhead crane operations.

The Importance of Collision Avoidance Systems in Overhead Crane Operations

In the realm of overhead crane operations, ensuring safety is of paramount importance. These heavy-duty machines are responsible for lifting and transporting loads in various industrial settings. The nature of overhead crane operations, with their elevated movements and proximity to workers and equipment, poses inherent risks. Therefore, the implementation of collision avoidance systems designed specifically for overhead cranes has become increasingly crucial.

Collision avoidance systems play a pivotal role in preventing collisions involving overhead cranes, including crane-to-crane, crane-to-wall, and crane-to-storage system collisions. By utilizing advanced technologies and intelligent algorithms, these systems effectively detect potential collision hazards and initiate preventive measures in real-time. Through their functionality, collision avoidance systems safeguard the safety of operators, protect the integrity of the shop, and contribute to the overall productivity and efficiency of overhead crane operations.

What is a Collision Avoidance System for Overhead Cranes?

In the context of overhead crane operations, a collision avoidance system is a sophisticated technological solution designed to prevent collisions between overhead cranes or their loads and other objects within the operating area. These systems utilize a combination of sensors, detectors, and intelligent algorithms to continuously monitor the crane’s surroundings and detect potential collision risks.

How Collision Avoidance Systems Work to Prevent Overhead Crane Collisions

Collision avoidance systems for overhead cranes employ various components and technologies to prevent collisions. These systems typically include:

Sensors and Detectors: Collision avoidance systems utilize sensors such as laser scanners, cameras, or proximity sensors to detect the presence of other cranes, walls, storage systems, or any fixed or moving objects within the operating area. These sensors continuously monitor the surroundings and provide real-time data.

Intelligent Algorithms: Advanced collision avoidance systems incorporate intelligent algorithms that analyze the sensor data and assess potential collision risks. These algorithms are designed to recognize collision trajectories and calculate safe distances between the crane and surrounding objects.

Real-time Alerts and Intervention: When a potential collision risk is identified, the collision avoidance system triggers visual or audible alerts to notify the crane operator. These alerts serve as immediate warnings, allowing the operator to take appropriate action to prevent a collision. In some cases, the system can also intervene autonomously by adjusting crane movements or even halting operations if necessary.

Overview of the Components and Technologies Involved in Collision Avoidance Systems

Collision avoidance systems for overhead cranes utilize a combination of components and technologies to ensure effective collision prevention. These may include:

- Laser Scanners: Laser scanners use laser beams to measure distances between the crane and surrounding objects. By constantly scanning the environment, they provide accurate real-time data for collision risk assessment.

- Proximity Sensors: Proximity sensors, such as ultrasonic or infrared sensors, detect the presence of objects in close proximity to the crane. These sensors are often used in conjunction with other detection technologies for comprehensive coverage.

- Cameras and Vision Systems: Cameras and vision systems capture visual information of the crane’s surroundings. They provide additional data for collision detection and enable the system to recognize objects and their movements.

- Intelligent Software and Algorithms: Advanced software and intelligent algorithms process the data from various sensors to analyze the crane’s environment, detect potential collision risks, and make real-time decisions to prevent collisions. These algorithms take into account factors such as crane speed, load weight, and operating parameters to ensure accurate collision detection and prevention.

By combining these components and technologies, collision avoidance systems for overhead cranes provide a robust safety net, helping operators and businesses mitigate the risks associated with crane collisions and ensuring a safer working environment.

Benefits of Collision Avoidance Systems for Operator Safety in Overhead Crane Operations

Crane-to-crane collisions pose significant risks to the safety of operators and surrounding personnel. The sheer weight and momentum of the cranes, coupled with the potential for falling objects or structural damage, can result in severe injuries or even fatalities. Operators and workers in the vicinity of the collision are at risk of being struck by moving cranes, falling debris, or dislodged loads.

How Collision Avoidance Systems Mitigate the Risk and Protect Crane Operators

Collision avoidance systems play a crucial role in preventing crane-to-crane collisions and protecting operators. These systems continuously monitor the positions and movements of multiple cranes operating in the same area. By analyzing the data from sensors and detectors, the collision avoidance system can detect potential collision trajectories and calculate safe distances between cranes. In the event of an imminent collision, the system triggers immediate alerts to operators, allowing them to take evasive actions and avoid accidents.

By providing real-time situational awareness and warnings, collision avoidance systems empower operators to make informed decisions and effectively prevent crane-to-crane collisions. This ensures the safety of crane operators and reduces the risk of injuries in busy industrial environments.

Prevention of Crane-to-Wall and Crane-to-Storage System Collisions

Collisions between overhead cranes and walls or storage systems can result in significant damage to infrastructure and storage equipment. The impact can cause structural deformities, compromise the integrity of walls or shelves, and lead to costly repairs or replacements. Such collisions also pose a risk of damaging valuable inventory, leading to financial losses for businesses.

Role of Collision Avoidance Systems in Maintaining the Integrity of the Shop

Collision avoidance systems effectively prevent crane-to-wall and crane-to-storage system collisions by detecting potential collision risks and initiating preventive measures. The system continuously monitors the position and movement of the crane, as well as the proximity to walls and storage systems. If the crane approaches a predefined safety threshold, the collision avoidance system provides immediate alerts to the operator, allowing them to adjust their movements and avoid collisions.

By preserving the integrity of walls and storage systems, collision avoidance systems contribute to a safer working environment and prevent costly damage to infrastructure and valuable inventory. This ensures smooth operations, minimizes downtime for repairs, and maintains the overall efficiency of the shop.

Benefits of Collision Avoidance Systems for Shop Integrity in Overhead Crane Operations

Collision avoidance systems play a crucial role in preserving equipment and minimizing damage. By continuously monitoring the crane’s surroundings, these systems detect potential collision risks with other objects or equipment in the shop. When a collision risk is detected, the collision avoidance system provides immediate alerts to the operator, allowing them to take preventive actions and avoid the collision.

By preventing collisions, these avoidance systems protect the shop’s assets, ensuring the longevity and functionality of equipment. This reduces the need for costly repairs or replacements, minimizes downtime, and maintains optimal productivity and operational efficiency.

How Collision Avoidance Systems Help in Reducing Downtime and Repair Expenses

Collision avoidance systems help in reducing downtime and repair costs by preventing collisions in the first place. By providing real-time alerts and warnings, these systems enable operators to take immediate corrective actions, avoiding collisions and the subsequent need for repairs. This minimizes the downtime required for repairs, allows operations to resume quickly, and ensures the smooth flow of work.

By reducing downtime and repair expenses, collision avoidance systems contribute to improved operational efficiency, optimized productivity, and cost savings for the shop.

Zenar’s Commitment to Collision Avoidance

Zenar is at the forefront of advanced collision avoidance technology specifically designed for overhead cranes. Our collision avoidance system combines state-of-the-art sensors, intelligent algorithms, and seamless integration with crane operations to ensure maximum safety and efficiency.

Integration of Features like Semi-Automatic Positioning and No-Fly Zones

Zenar’s collision avoidance system incorporates additional features to enhance its functionality. One such feature is the semi-automatic positioning capability, which allows operators to select a predefined position and transport the crane from its current position to the desired location with a simple command. This feature saves time, increases operational efficiency, and ensures accurate positioning of the load at a safe height.

Another integral part of Zenar’s collision avoidance system is the implementation of no-fly zones. These predetermined no-fly zones prevent the overhead crane from flying over designated areas where other equipment or shelving systems are permanently stationed. By combining collision avoidance technology with no-fly zones, Zenar’s system ensures real-time response and automatic avoidance of no-fly zones, improving safety and preventing potential collisions.

How Zenar’s System Ensures Real-Time Response and Automatic Avoidance

Zenar’s collision avoidance system leverages advanced sensors, detectors, and intelligent algorithms to provide real-time response and automatic avoidance. The system continuously monitors the crane’s surroundings, detecting potential collision risks and calculating safe distances. When a potential collision is detected, the system triggers immediate alerts to the operator, prompting them to take corrective actions. In critical situations, the system can also intervene autonomously to adjust crane movements or halt operations, preventing collisions and ensuring the safety of personnel and equipment.

Zenar’s collision avoidance system is designed with precision, considering the unique challenges and requirements of overhead crane operations. By seamlessly integrating with the crane’s functionalities and providing real-time response, Zenar’s system enhances safety, minimizes the risk of collisions, and maximizes the efficiency of overhead crane operations.

Zenar’s collision avoidance system stands as a testament to our commitment to safety and efficiency in overhead crane operations. With its advanced technology, integration of features like semi-automatic positioning and no-fly zones, and real-time response capabilities, Zenar’s system provides operators with a comprehensive solution to minimize collision risks and maximize operational performance.

Trust Zenar For Your Overhead Crane Solutions

Don’t compromise on safety and reliability. Contact Zenar today to discuss your overhead crane requirements and experience the peace of mind that comes with partnering with a trusted industry leader. Your operators’ safety and the integrity of your shop are our top priorities, and we are ready to exceed your expectations.

Together, let’s build a safer and more productive working environment. Contact us now to explore our range of overhead crane solutions and benefit from our expertise in collision avoidance systems.

Read

More

Articles

How Zenar Cranes Are Designed for Safety & Reliability

When it comes to heavy lifting, safety and reliability aren’t just important—they’re absolutely non-negotiable. In an industry where machinery routinely operates under extreme conditions, Zenar Cranes have earned their reputation as trusted workhorses thanks to their robust design and advanced features.

8 Ways to Avoid Costly Crane Repairs

Overhead cranes play a pivotal role in the efficiency of industrial operations, serving as critical equipment in the movement and lifting of heavy materials. However, when these cranes falter, the financial repercussions from repairs, lost productivity, and enhanced safety risks become significant.

Troubleshooting Techniques for Overhead Crane Electrical Problems

Nestled within the bustling heart of the industrial sphere, overhead cranes stand as monumental testaments to human engineering and ingenuity. These mechanical behemoths are indispensable in a myriad of sectors, from construction to manufacturing, playing a pivotal role in the lifting and transportation of heavy materials. Yet their pivotal role comes with its set of challenges, especially when it comes to maintaining their electrical integrity.